Cement Industry

Cement Industry In each section of cement plant, storage and transportation system plays a decisive role. For example, raw material homogenization and transportation, clinker storage and transportation, as well as finished cement storage, conveying and distribution. SRON provides bulk material storage and transportation system solutions for cement plant customers. Cement Storage and Transportation System SRON […]

Cement Industry

In each section of cement plant, storage and transportation system plays a decisive role. For example, raw material homogenization and transportation, clinker storage and transportation, as well as finished cement storage, conveying and distribution. SRON provides bulk material storage and transportation system solutions for cement plant customers.

Cement Storage and Transportation System

SRON provides customers with welded steel silos, bolted steel silos, spiral steel silos and other structural types of finished cement silos. SRON cement steel silo has characteristics of good sealing performance, short construction period, small footprint, and low construction and operation cost. SRON can design various types of silos of which single silo storage capacity is 0.1-30,000 tons to meet customers’ needs. The cement silo is equipped with a fluidization discharging system to achieve the homogenization of cement in the process of cement feeding and discharging.

SRON provides customers with system solutions and services for cement storage and transportation, bulk loading of tank truck, and bag packaging, etc.

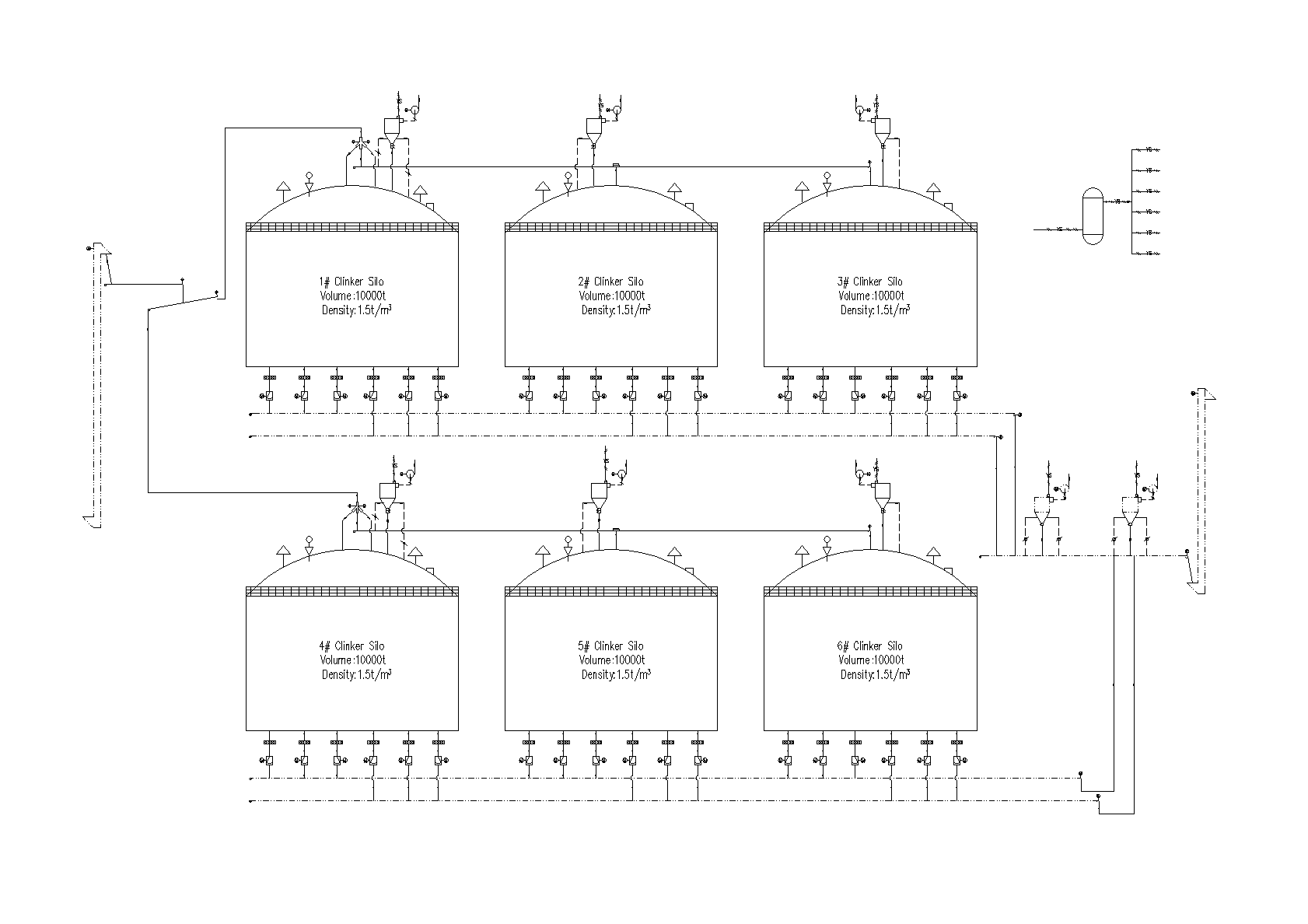

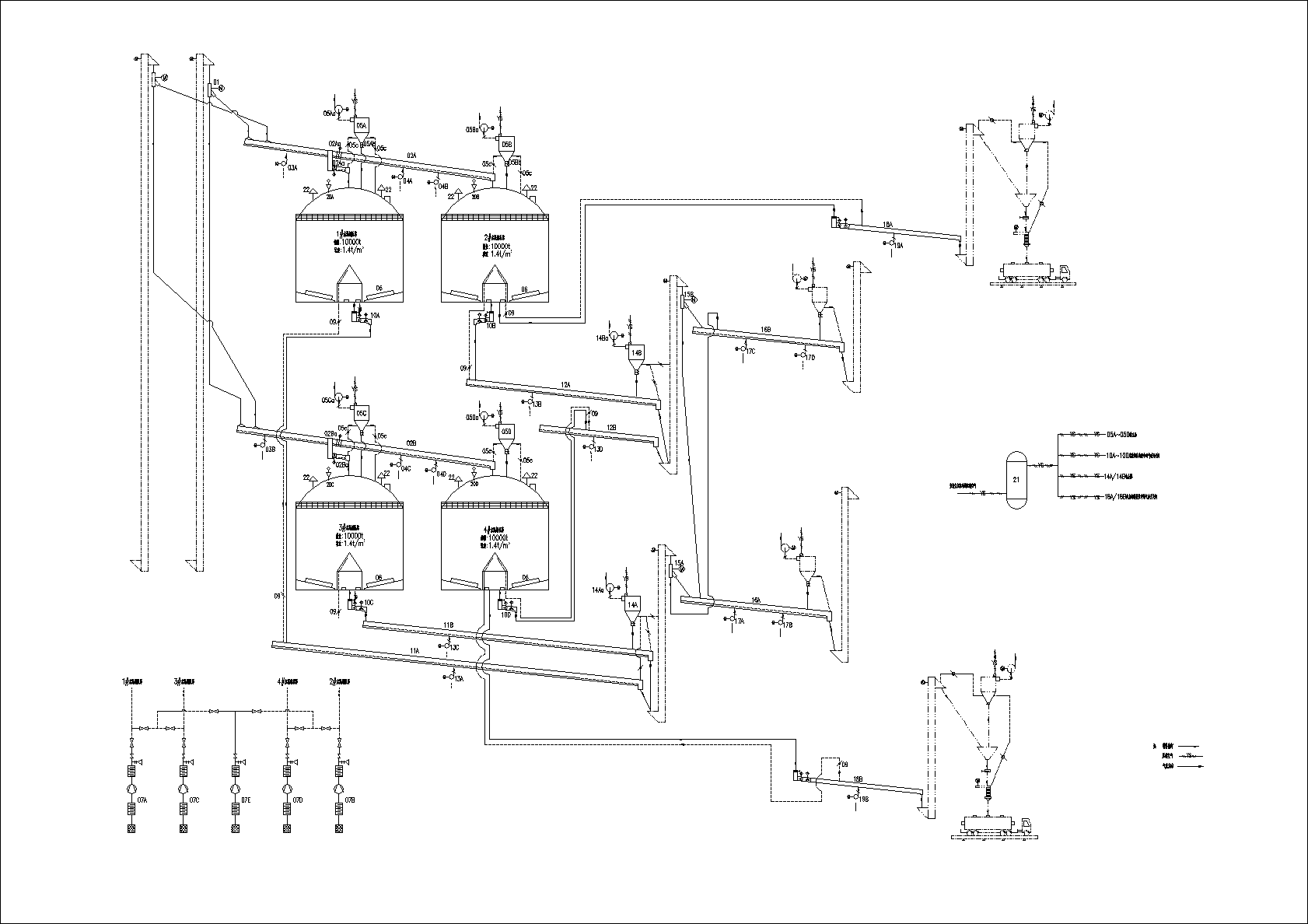

Clinker Storage and Transportation System

You can use steel silos, high wall silos and tent-shaped warehouse to store clinker. The storage capacity of a steel silo is 1-50,000t, and the silo body is steel structure. It is characterized by small footprint, short construction period and low construction cost. The storage capacity of a high wall silo is 1-100,000t, the silo wall is reinforced concrete retaining wall, and the silo roof is grid structure. It is characterized by small footprint, and large storage capacity. The tent-shaped warehouse is conical, consisting of the bottom concrete retaining wall and steel structure grid frame. The advantages of the warehouse are good cooling effect and low requirements for bearing capacity of the foundation.

Cement Mixing System

Cement mixing system has three main subsystems: Slag powder and limestone powder and OPC powder storage system; Slag powder and limestone powder and OPC powder mixing and stirring system; Finished cement feeding and discharging system. The cement mixing system can produce many kinds of cement by mixing different materials such as slag powder, fly ash, limestone powder and cement. SRON cement mixing system has features of low construction cost, short construction period and high precision of continuous metering mixing, which can bring significant economic benefits to customers.