Large Welded Steel Silo

Capacity: 1000ton~100,000ton (Base on cement 1.3ton/m3)

Diameter: 11m~83m (Approx.)

Material: Can be used for granular and powder material.

Body panel thickness: 6mm-25mm;

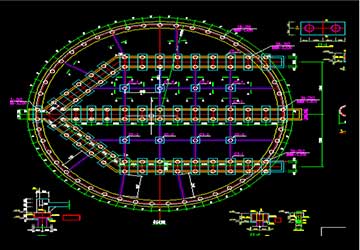

Structure: Body panel are flat panel, with circular stiffener and vertical stiffener, body panel is thicker, silo roof structure usually adopt truss structure, when silo diameter is large or heavy load required on silo roof, can use grid structure.

Introduction

Large welded steel silo, mainly made of steel, is an independently developed silo type in the continuous development of national steel silo industry, suitable for storing cement, clinker, fly ash, and other the bulk materials

The effective diameter of large welded steel silo can reach tens of meters. Silo body is cylindrical, the silo roof is spherical, and silo wall is the form of steel structure frame. The maximum single silo capacity can reach 80,000 tons. SRON has obtained more than 20 patents in silo process design and internal structure of silo, and has scientific and advanced silo design concepts to create maximum economic benefits for customers.

Features and Advantages

Structural safety: As a thin-walled container with high load, structural safety of steel silo must be the most important thing. In the early design stage of each silo, SRON will fully consider various dead load, dynamic load, material load, earthquake load, wind load, snow load, temperature effects,etc.

High welding quality: Strict welding process. Ensuring the quality of each weld in accordance with ISO 15607 welding process procedures.

Large storage capacity: the diameter of the silo is 80m, and the capacity of a single silo is 5,000-80,000 tons, which can be increased if there are special needs;

Low initial investment: due to the adoption of a number of patented technologies, it can save about 50% of building materials and more than 60% of land to be acquired;

It has good air tightness and adopts patent technology of vacuum sealing. The physical indexes of cement quality are basically unchanged within 9 months of storage inside the silo;

Energy saving and environmental protection: patented dust removal technology is used in the process of warehousing and outbound, which will not cause pollution to the surrounding environment;

High strength, long service life, with to the standard maintenance, service life up to 30-50 years.

As a high-load thin-walled structure building, the safety of the steel silo has a high priority. SRON engineer fully consider various factors, like dead loads, dynamic loads, grain loads, earthquakes, wind loads, snow loads, temperature effects, etc. in the early design stage of silo system.

For overseas projects, we fully consider the differences of national standards, uses international standards and professional industry software such as STAD PRO and SAAP2000, and uses finite element analysis to produce effective structural calculations.

Supporting equipment

Leveling & Surveying

Foundation excavation

Formwork and reinforcement

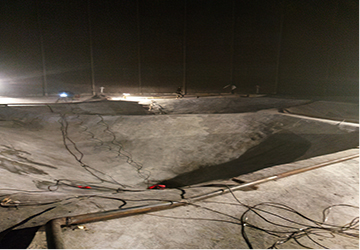

Concrete pouring

Installation for silo roof

Silo-body installation

Rust removal and anticorrosion

Masonry construction in silo

Gasification facility installation

Discharge installation

Electrical equipment installation

Completion

Please feel free to give your inquiry in the form below.

We will reply you in 24 hours.

Pneumatic conveying, bucket elevator, dust collector, air chute, silo bottom discharge device,gasification box, radar level meter, level switch, bulk loading machine, etc