Fast Loading Station

Single suit loading capacity: ≥5500t/h

Loading form: single bin and single rail (single bin and double rail, double bin and double rail)

Effective capacity of Surger Bin : ≥300 tons

Effective capacity of Weigh Bin : ≥100 tons

Applicable train models: professional design based on the user’s actual train models to meet the user’s loading requirements

Loading speed: ≤50 seconds/section (C80), the loading time for a whole train is less than 1 hour

Weighing accuracy: static weighing accuracy ± 0.1%

Loading accuracy: single section loading error ≤ ± 0.1%

The whole train loading error: ≤ ± 0.05%

Introduction

RAPID & QUANTITATIVE TRAIN LOADING SYSTEM

The SRON rapid & quantitative train loading system is an international advanced metering instrument, which integrates the mechanical, hydraulic and electric control technical. It can realize continuous weighing and loading through fast loading and accurate metering, as well as automatic control of matched conveying system. It is the most advanced train loading system for coal, ore and bulk materials at present.

RAPID & QUANTITATIVE TRUCK LOADING SYSTEM

The SRON rapid & quantitative truck loading system is designed based on the large hopper scale. It can carry out batching and accurate weighing in the weighing cabin according to the load of the truck in advance by the accurate control of the weighing.cabin gate. Once the truck is in place, the quick and accurate measuring loading will be realized by controlling the discharge gate and loading chute, or by the precise control of the material inventory in the weighing cabin. It is one of the most advanced loading method for bulk material.

Features and Advantages

RAPID & QUANTITATIVE TRAIN LOADING SYSTEM

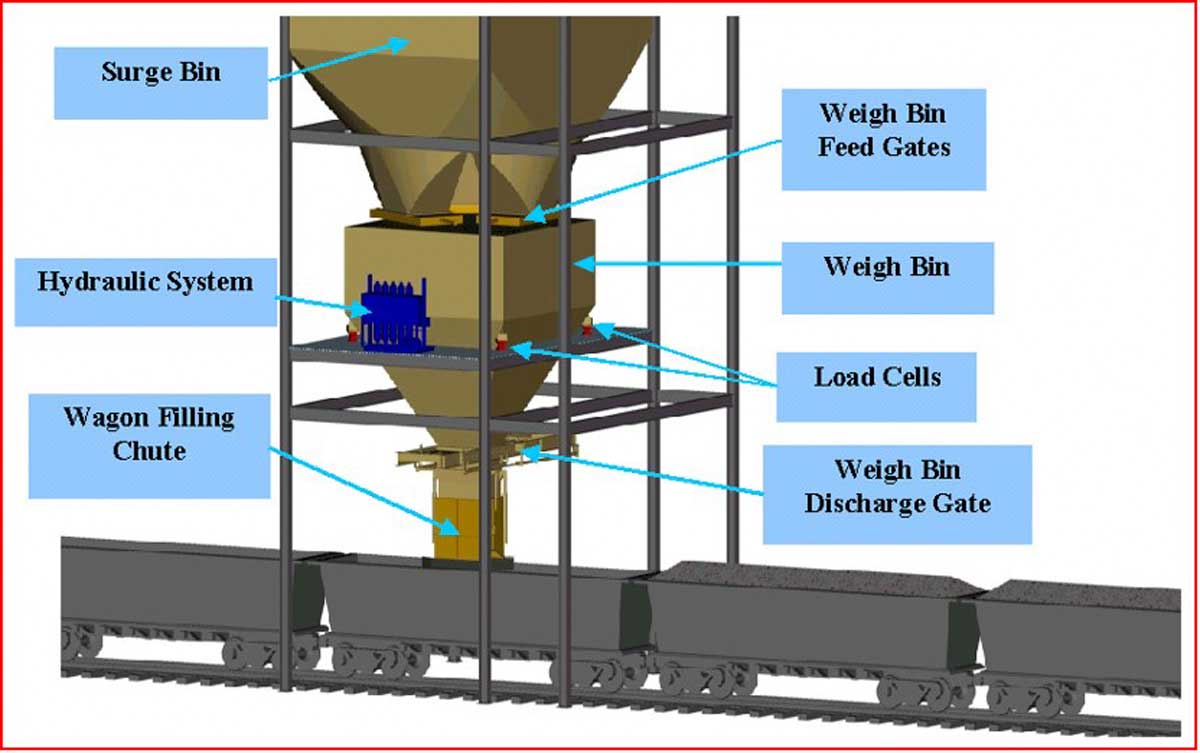

System Structure

The SRON rapid & quantitative train loading system is mainly composed of steel structure tower, loading equipment, weighing system, hydraulic system, electronic control system, computer control system, etc., to realize the operation control, protection, monitoring and display of all relevant equipment in the whole process of train loading.

It is suitable for loading of coal, ore, grain, chemical raw materials and other bulk materials. It is widely used in coal mines, ports, docks, collecting stations and so on.

Technical Highlights

Intelligent dust suppressant spraying system: the system includes liquid system and spraying system, it can realize automatic lifting and spraying, frost and thaw resistance, wind erosion resistance.

Intelligent train leveling and compacting device: the leveling time of each train has been reduced from 4 hours to less than 1 hour at present, which improving efficiency and reducing cost.

Technical Parameters

Single suit loading capacity: ≥5500t/h

Loading form: single bin and single rail (single bin and double rail, double bin and double rail)

Effective capacity of Surger Bin : ≥300 tons

Effective capacity of Weigh Bin : ≥100 tons

Applicable train models: professional design based on the user’s actual train models to meet the user’s loading requirements

Loading speed: ≤50 seconds/section (C80), the loading time for a whole train is less than 1 hour

Weighing accuracy: static weighing accuracy ± 0.1%

RAPID & QUANTITATIVE TRUCK LOADING SYSTEM

System Structure

It is mainly composed of large steel structure tower, loading equipment, weighing system, hydraulic system, electronic control system, computer software system, etc.

It is suitable for loading of coal, ore, grain, chemical raw materials and other bulk materials. It is widely used in coal mines, ports, docks, collecting stations and so on.

Technical Parameters

SRON rapid & quantitative truck loading system has several types: single channel, double channel and multi-channel

loading system. The technical parameters of single channel quantitative loading system are as follows:

Loading capacity: 2500-3500t/h

Buffer silo capacity: 200 t

Measuring accuracy of equipment: ±0.1%

Loading accuracy: < ±0.1 %

Loading speed: ≤120S / per cycle

Adaptation models: various truck models

Hydraulic Control System

SRON hydraulic control system follows the principle of energy saving, fast response, high reliability, smooth operation. The main pump, valve, cylinder are adopted the international famous brands, such as: Italy ATOS, UAS Parker, USA Vickers.

Automatic Lubricating System

SRON truck loading system adopts automatic pressure lubrication system, which lubricates all the key rotating parts according to the program-setting by the centralized lubrication pump station, so as to ensure the lubrication effect of the equipment. It improves the service life of heavy-load supporting roller and loading chute rolling bearing, so the system can works stably and reduce the manpower maintenance.