Bulk Material Stockyard

Brief introduction: A bulk material stockyard is a storage facility designed for large quantities of dry, solid materials like minerals, ore, coal, or grain. It is a site for receiving, storing, processing and mixing materials.

Type:Closed, Open-air

Equipment: Reticulated Shell、Bucket Wheel Stacker Reclaimer、Belt Conveyor、Rubber Dust Curtain

Application: Mainly used in ports, docks, mines, metallurgy, cement plants, coal storage yards, coking plants, steel plants, power plants and other bulk material storage yards.

Introduction

bulk material stockyard

A bulk material stockyard is a storage facility designed for large quantities of dry, solid materials like minerals, ore, coal, or grain. It is a site for receiving, storing, processing and mixing materials. These yards typically involve stacking and reclaiming operations, and can be configured as strip or circular stockyards(spherical stockyard). They are essential for bulk material handling, connecting various stages in the supply chain and facilitating efficient storage and mixing of materials.

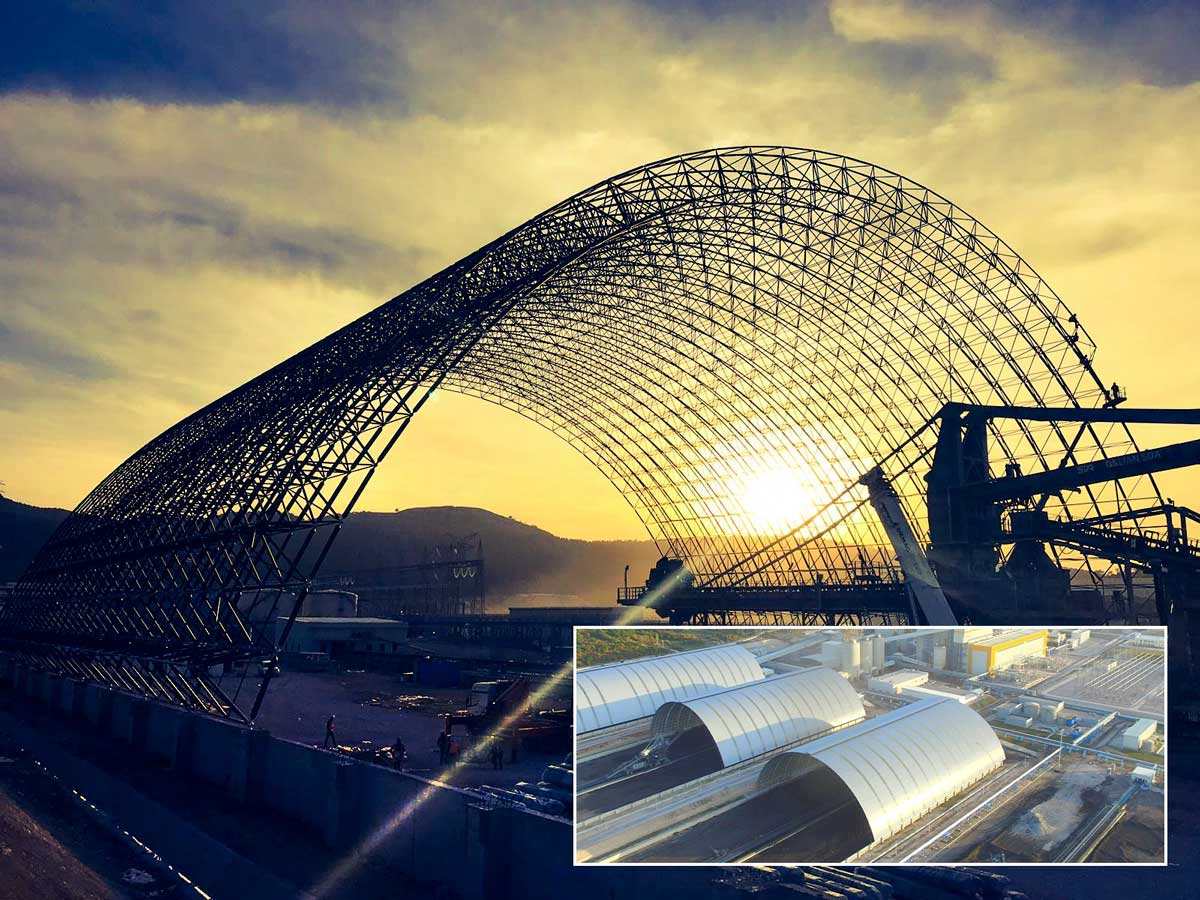

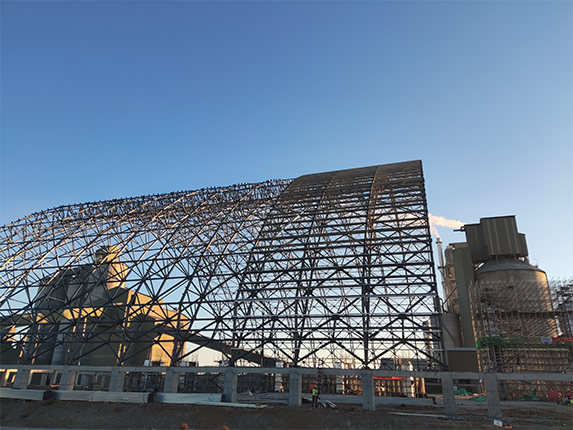

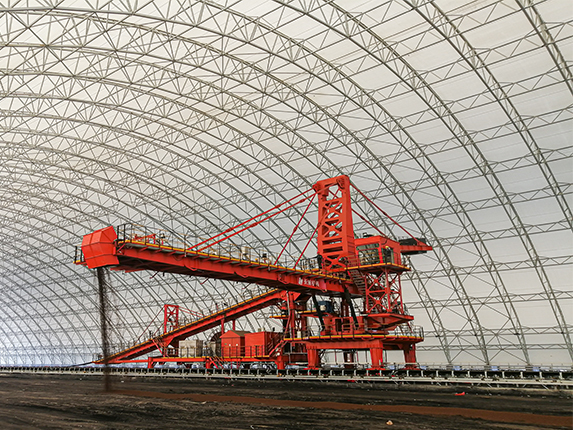

Strip Stockyard

In the conveying system of various industries, strip stockyard is responsible for the storage and distribution of materials, and has dual functions of storage and homogenization. Strip stockyard adopts a grid structure, and stacker reclaimer is used to complete the mechanized stacking and reclaiming. SRON can select and design stacking and reclaiming methods according to project scale, actual situation of clients and site conditions.

Type:Closed, Open-air

Equipment: Bucket Wheel Stacker Reclaimer、Belt Conveyor、Rubber Dust Curtain

Application: Mainly used in ports, docks, mines, metallurgy, cement plants, coal storage yards, coking plants, steel plants, power plants and other bulk material storage yards.

Circular Stockyard

The top of circular stockyard is spherical grid structure and its bottom is reinforced concrete retaining wall. Circular stockyard uses central reclaimer to complete the stacking and reclaiming operations. The diameter of a circular stockyard is generally between 60~120m. The cantilever stacker at the top of the central column can rotate and pitch around the central column in a range of 360 degrees. Circular stockyard covers an area of circular shape, which is adaptable.

Features and Advantages

Key Features and Functions of Bulk Material

Stockyard:Storage:Stockyards provide temporary storage for bulk materials before they are processed or shipped.

Mixing and Blending: Depending on the needs, the material yard can be equipped with equipment to mix different types of materials to achieve the required quality.

Material Handling: stockyard utilize equipment like stackers and reclaimers to move and store materials efficiently.

Inventory Management: stockyard management systems can provide real-time data on material inventory and optimize storage and handling operations.

Types: Strip stockyards use linear storage, while circular or spherical stockyards use a circular storage layout. Different material yard types can be selected according to different industries and application scenarios.

Equipment: Common equipment includes stackers (to create stockpiles), reclaimers (to retrieve material), and belt conveyors.

Applications: Stockyards are found in industries like mining, cement production, port facilities,.

Considerations for Stockyard Design and Operation:

Material Properties:The type of material (e.g., coal, ore, cement) affects storage methods and equipment choices.

Storage Capacity:The required storage volume and material flow rates determine the stockyard design.

Environmental Factors:Stockyards may require measures to prevent dust, runoff, and other environmental impacts.

Equipment Selection:The choice of stackers, reclaimers, and conveyors depends on the specific material, storage capacity, and operational needs.

Features of Strip Stockyard

1. Less equipment investment, low energy consumption, low use cost and high production efficiency.

2. Reasonable structure and good equipment stability.

3. Good mixing effect and strong material adaptability.

4. Simple operation, safe and reliable, easy to realize mechanization and automation.

5. Easy to implement, low operation and maintenance costs.

Features Of Circular Stockyard

1. Small footprint and high site utilization.

2. Advanced technology, safe and reliable operation.

3. Low investment cost, continuous and simultaneous stacking and reclaiming operations.

4. Strong resistance to bad weather and good landscape.

5. Outstanding environmental protection performance and low loss.

Technology

Please feel free to give your inquiry in the form below.

We will reply you in 24 hours.

Choice of Closed Stockyard and Open-air Stockyard

Open-air stockyards have been widely used in power plants, building materials, mines, ports, and metallurgy industries. In the storage and processing of bulk materials, the material storage method of the open-air stockyard has the advantages of flexible process layout, mature process technology, high reliability of process equipment, mature civil engineering and other supporting facilities, etc. However, for the storage of bulk materials with special requirements such as moisture-proof, rain-proof, wind-proof, cold-proof and freeze-proof, closed stockyards are a better choice, and closed stockyards have obvious advantages over open-air stockyards in terms of energy saving, environmental protection, consumption reduction and land saving.